Here’s a legacy look at a hardware project I created with my friend Derek Scott.

Can I use GarageBand with beatseqr?

Beatseqr version 4 function layout

Since I haven’t tackled a final silk screened top plate for version 4, I thought I’d at least lay out something in a graphic so you could see what this version of beatseqr does.

font: Masking Tape Block

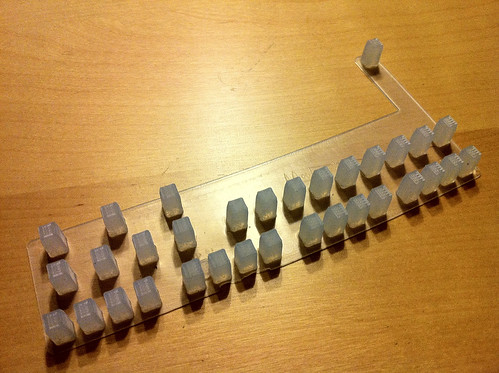

Monolithic button array!

Woohoo! I’ve been working on trying to get this monolithic button array figured out for months, and I finally have it all dialed in.

So this, along with the major progress (as seen below) I’ve been making with the new cases, I’m feeling pretty good about beatseqr version 4!

If you’re really interested in how I make my silicone buttons, I wrote an extensive article on my fine art blog about it. Check it out!

Beatseqr on Moving Air, NYC edition

Derek and I were out in NYC for the first ever World Maker Faire, and on our extra day in the city after the show, Derek put me on with my beatseqr for an improvised unscripted demo… Normally, we play as a group with a couple of beatseqrs going, so it became somewhat obvious to me half-way through that I need to tweak my live solo set up. But it was fun and then Derek of course played an awesome set of techno as per usual.

Catch Moving Air on Common Ground Radio, monday nights 7-9pm PDT http://bit.ly/commongr8

beatseqr at World Maker Faire New York 2010

We are coming to NEW YORK CITY in a little over a week! Come see us at World Maker Faire in Queens!

Beatseqr v4.0 cnc routed case

Here’s the first look at version Beatseqr v4.0 in the new case:

I had to look high and low to find sources for the right size project box. It’s been a big challenge to balance cost, availability, feasibility, and also consider the fabrication work flow when selecting this type of case. I’ll be honest in that I’d prefer to have super nice solid wood, or unibody aluminum cases. That would be friggen’ sweet. But… 1. wood cases are extremely time consuming to build. I *will* offer custom wood cases for an additional fee. And, 2. aluminum is expensive, and my tool set really isn’t appropriate to work with it at this time… so we’ll have to settle for our dreams for now. The case I’ve selected is a good candidate for custom paint jobs, and the way all of the parts mount to it is the easiest we’ve ever had. So this is a pretty good case.

After I located the right cases, I reformatted the circuit to fit onto the appropriate board dimensions for the case. I’m still unable to offer the circuit boards as open source designs at this time, but I’m hoping to loom more into that in the next year or so.

Next, I had to work out a set of CNC gcode to reproducibly route all of the mounting and component holes on the circuit boards. The complications here were in the increased precision I now get to.. enjoy (?) working with, due to the new cases and strict requirements for mounting holes. Previously, mounting the board to the case involved custom drilling holes into the top panel, towards the very end of the process, and now the entire process has flipped. Now I work from the case on down instead of circuit board on up. It’s something I didn’t really think about until I started seeing all of the repercussions once I had my new boards and was cutting holes in the cases. But it’s pretty good now.

Then finally, I’ve been spending a bunch of time dialing in the CNC gcode for the case, as you can see below:

Here’s the aftermath on the blacktoe after several trial and error runs on layout designs.

Here are a few photos of “close but no cigar” runs. You can see that the early tests had holes in the wrong places.

Check out this video of what the cutting process is like. Sorry for Mr. Shaky Cam. I ordered an iPhone 4 tripod mount, so I’m hoping the quality of my videos is going to improve soon.

Beatseqr version 4.x assembly video

As usual, when you don’t hear from us, we’re cooking up new stuff. Here’s the assembly video for the version 4.0 circuit board.

The main new features of version 4 are:

* changed form factor to accommodate being able to be placed in a new case that I’ve sourced.

* added a parameter record button. This is going to be awesome, so more info will come when we’ve been able to bake the sequencer more for this feature.

* improved the placement of the arduino mega so that the USB port is closer to the edge of the board

* improved all of the hole sizes for the LED tact buttons

* when I though to, I added secondary holes for potentiometers in case you ever need that.

* added a small prototyping area for ad-hoc needs.

* hardwired the mode button LEDs up to 5V so that they’re on all the time, which freed up three pins on the arduino. One of those was used for the parameter record button

* TWO UNUSED PINS. They’re digital in, and PWM out. You could put two more buttons on here, or switches, or LEDs… or serial devices and drive input/output with softwareserial in the arduino code. You could, in theory, add two more LCD screens using the moderndevice.com driver boards or similar serial input display drivers. All kinds of things. Oh, Maybe you want to add a couple of midi ports? Hmm!

* generally labeled a lot of things on the board so you know what you’re looking at.

* had to rewire an awful lot of stuff to make the autorouter happy. So consequently, the firmware has changed somewhat significantly. I don’t exactly know what the right method is going to be to keep the 3.x units up to date, but we’ll get something figured out.

known problems:

* one of the buttons needs a jumper wire to ground. I’ll certainly get that fixed next time I order boards, but it’s an extremely minimal bug fix to perform.

Arturo G’s beatseqr demo video

yeah, nice video!!

Kits: Serial numbers 1, 2, and 3

Okidoke. It’s taking me a while to get my act together, but I’m getting there. I have three kits available. They are kit serial numbers 1, 2, and 3.

The kit includes:

1. circuit board

2. eight 10k faders

3. two 10k potentiometers

4. thirty two LED Tact buttons (16 red, 16 green)

5. sixty four 100 ohm resistors

6. 9 various values of resistors other than 100 ohms

7. 16 x 2 LCD screen from Modern Device

8. LCD driver board kit (assembly is required) from Modern Device (where you will get the assembly instructions, BTW)

Things *not* included:

* Arduino Mega

* enclosure + hardware

Price is $249 plus shipping, payment via paypal, shipment via USPS if international, UPS if within the USA.

I even made two videos showing how to assemble the kits, so watch these before you do anything else. Make sure these totally makes sense to you, and you have no reservations about your ability to put this kit together. It’s not a particularly hard kit to put together, but there is a lot of repetitive soldering involved, so you’re the right candidate if you’re already comfortable with soldering, and you already have all of the tools you see in the videos. You’re also already familiar with the arduino platform and ALSO completely realize that this kit runs on the ARDUINO MEGA, and NOT any other variant. If you don’t have an ARDUINO MEGA, you NEED to BUY one. 🙂 I’m using every single pin on the mega. I couldn’t squeeze this much functionality out of a regular arduino… it’s just too awesome for the little guy.

You have to file down the headers because of where I chose to place the arduino mega. This is sort of cumbersome but it’s also how I was able to keep beatseqr from being any larger than it already is. The Roland TR-808 is cool and all, but c’mon already.. that thing is huge. Plus every square inch of circuit board costs big bucks, so squeezing the arduino into a shield configuration works well enough. I’d maybe try another tactic in the future, but this kits works today. I sold Beatseqr serial number 8 based on this kit.

Ok, so: 1. you read all of the above? 2. you saw both videos and aren’t tripping out? 3. you saw that you need an arduino mega? 4. still interested? email me steve at beatseqr dot com.

Announcements • Steppa v0.5

I am pleased to announce that MIDI sync out is working in Steppa as of version 0.5! Now you can sync your Beatseqr to any MIDI hardware or software that can receive MIDI clock, which opens a whole new world of possibilities. One scenario to imagine is being able to playback melody or bassline patterns that you previously created along side on-the-fly created drum patterns from Beatseqr. This can really be helpful if you use Beatseqr for live performing like we do for Haptic Synapses. We tested MIDI sync with software like Propellerhead Reason and Ableton Live as well as hardware like the Korg ESX-1…fun stuff!

Also added to Steppa 0.5 is the ability to sync to an audio click track. I know the technique sounds very old-school, but it works….well enough for Haptic Synapses and Antacid Crew to use it to sync all kinds of hardware (old and new) at their last jam session together at Mighty in San Francisco. So how do you like them apples?

Keep an eye on http://beatseqr.com for links to the new version and developing info about Steppa.