Nov. 17, 2023

Harbor freight has an affordable set:

Printable version of the harbor freight item above: https://www.thingiverse.com/thing:6308416

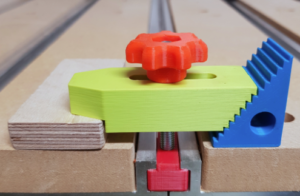

Here’s a similar idea using 3d printed long clamps. Printing them is a good idea in case you crash an end mill into it accidentally, but milling some out of Delrin or ABS might be stronger and more long lasting. https://www.thingiverse.com/thing:4168018

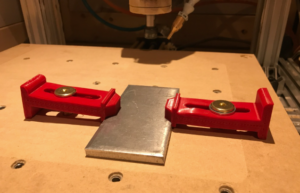

Another similar clamp that you would use the t-slots in the cnc’s table with, but same advice, purchase or mill out of aluminum or even plywood, if possible :

https://www.thingiverse.com/thing:4769680

Another long clamp. The idea is to keep the metal parts away from where the tool head is, in case of an accidental crash.

https://www.thingiverse.com/thing:4948898

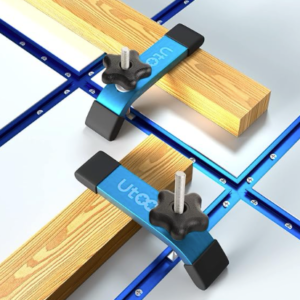

Aluminum versions are available, and arguably balance cost to strength well:

UTOOL 2 Pack T-Track Hold Down Clamps Kit, 6-1/3″ L x 1-1/5″ Width, Heavy Duty Anodized Clamps for Woodworking, Starlight Blue

Similar:

O’skool Multi-Positionable T-Track Hold Down Clamp Kit for CNC Router Clamp, Metalworking and Woodworking T-Slot T-Track Clamp,2 Pack

Similar:

T-Track Mini Hold Down Clamp Kit, 2Pcs Aluminum Alloy M6 T-Slot Hold Down Clamp, CNC Router Clamps for Woodworking and Metalworking-3.2″Lx1″Wx2.7″H

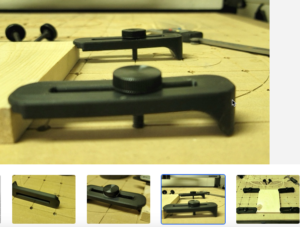

For higher risk but more repeatable fixturing, a cross sled vise can work, with the risk being crashing your end mill into metal. It definitely can work for special tasks but might not be a good generalist solution.

Nov. 19, 2023